Digitalisation of the Josef Underground Laboratory

The aim of the Digitalisation of the Josef Underground Laboratory project is to create a comprehensive digital ecosystem that will enable the effective collection, management and evaluation of data in real time. This will serve to increase the efficiency of teaching and experimental research at the Faculty of Civil Engineering of the Czech Technical University and will contribute to the development of modern methods for the purposes of the management, monitoring and safety of underground structures.

Digitalisation will further allow for the conducting of new types of projects that require simulations, as well as virtual tours and closer links with international research projects. The Josef Underground Laboratory will thus become a physical “Testbed for underground structures” (NCS4.0) and a digital testing and demonstration platform for innovations that connect the scientific community, industry and students in the field of underground technologies.

The Digitalisation project responds to the challenges that the construction industry will face in the future, focusing particularly on underground structures and aimed at:

- implementing a comprehensive digital management, operations and laboratory monitoring system

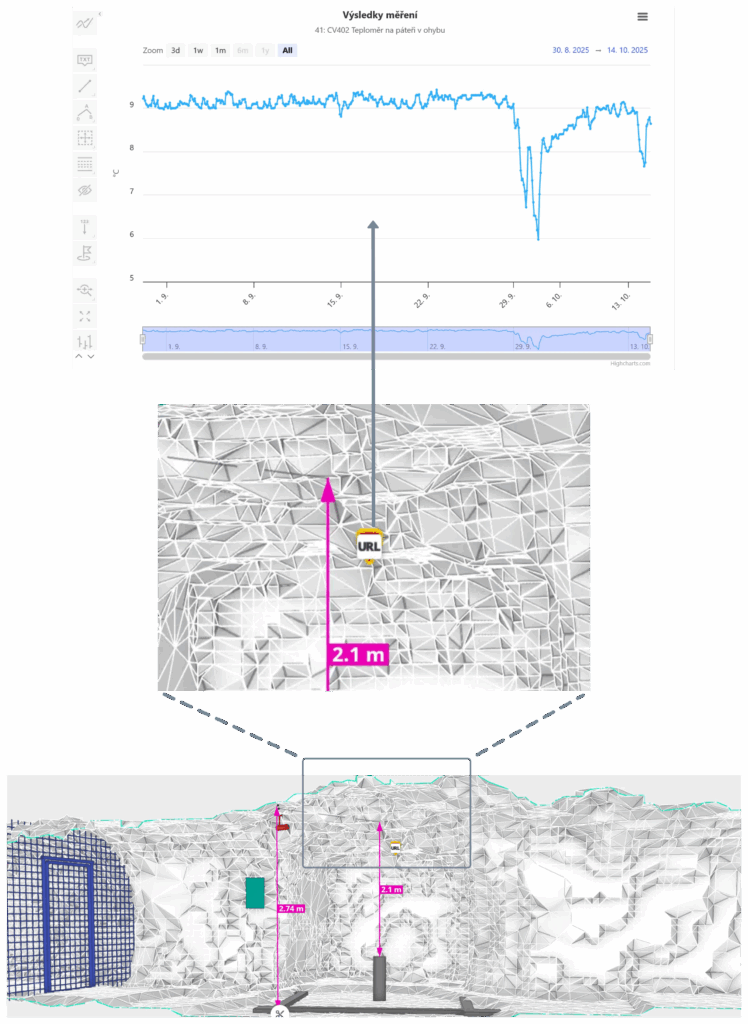

- integrating sensors, measurement instruments and data platforms into one unified environment

- enabling data analysis and visualisation via a digital model (the Digital Twin)

- supporting the safety, efficiency and sustainability of the operation of underground structures

creating an educational and research platform that connects academia, industry and students.

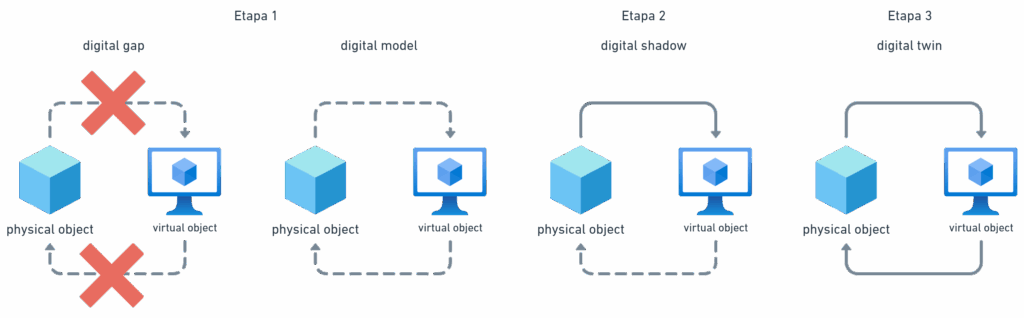

The Digitalisation concept was first discussed at the Robotics Underground event in June 2024. The ultimate objective comprises the practical application of a digital twin of the Josef underground gallery (former mining adit), which forms part of the Josef Underground Laboratory, via a platform developed and managed by the Czech Technical University in Prague.

The digital twin will integrate all the information relating to the underground gallery, including the experiments underway in the gallery, in real time. It will also allow for two-way communication, thus enabling the management of the gallery via the virtual twin environment.

The key features of the project comprise the creation of standardised open data, which will represent a source information platform for the full range of planned experiments and the robotisation process, and a platform for the potential simulation and optimisation of operational and research processes.

The Josef Underground Laboratory (a Faculty of Civil Engineering of the Czech Technical University facility) aims to become the first digital online underground mine workplace in the Czech Republic. The more accurate data collection and analysis methods, more rapid simulation and enhancement of the possibility to share results will serve to strengthen the overall scientific potential of the field of geotechnics.

Project phasing

The Digitalisation project is proceeding in the form of logical phases, and all the related data is being stored in a common data environment.

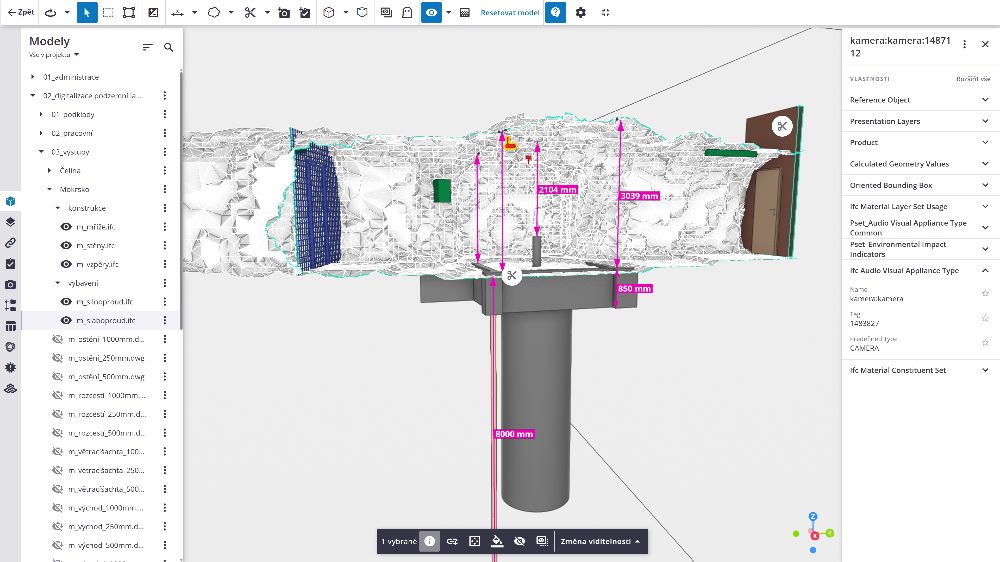

In addition to the storage function, CDE is employed for communication with respect to managing the digitalisation project. The main advantages of CDE concern its ability to open and work with documents as information carriers and to work directly with the information contained in the documents. It is possible to merge information taken from 2D drawings, point clouds and multiple BIM (Building Information Modelling) models, to add non-graphic information to individual BIM model components, add annotations and dimensions and to store prepared overviews of the respective files.

Phase 1

filling in the gaps concerning the knowledge of the gallery and the transformation of data to a BIM model

The basic concept behind the digital twin comprises the implementation of a digital information model (BIM model) of the underground gallery, which will be constructed in the form of a georeferenced, object-oriented model according to the ISO 16739 standard. This will ensure independence from SW tools with respect to both the creation of the model and its subsequent use. Thus, it will be possible to use information on the gallery over the long term without the risk of incurring additional costs due to increases in the prices of SW licences, the termination of support by the software supplier, etc. (i.e. the avoidance of vendor lock-in).

Phase 1.a

– spatial model of the gallery and its main structural components

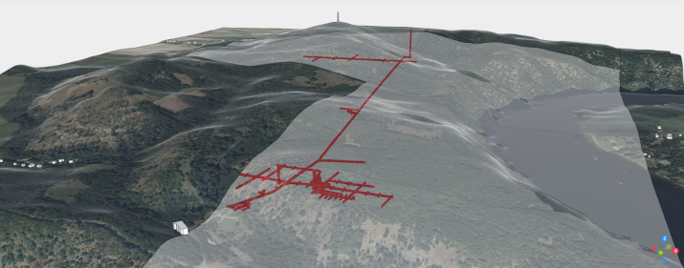

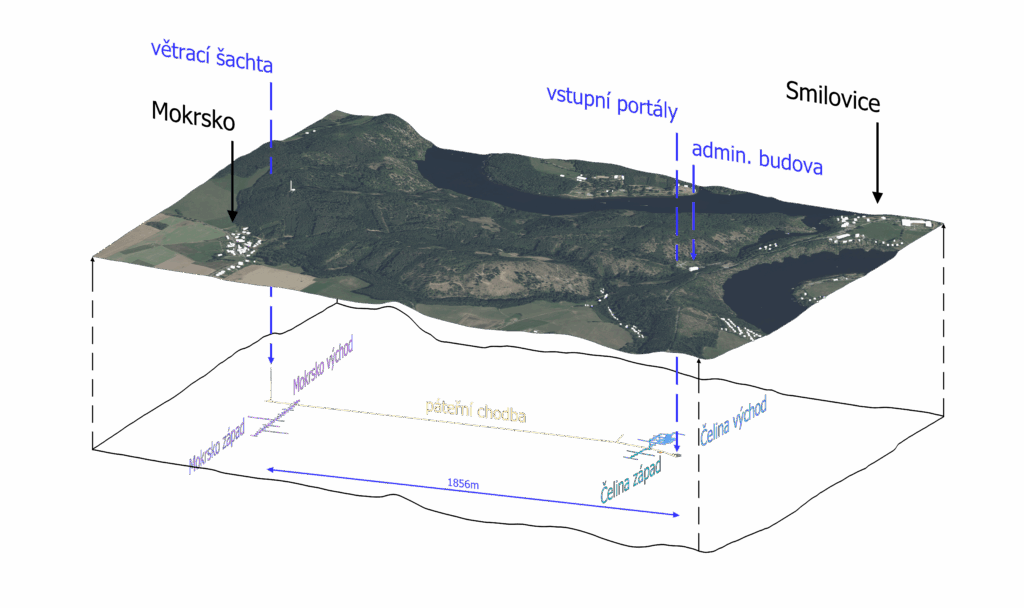

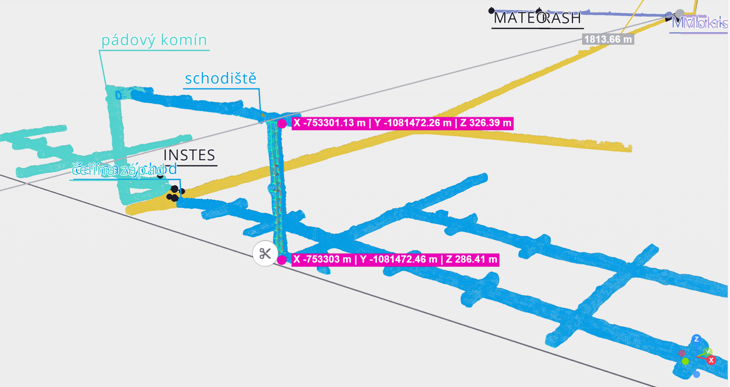

The first phase involves the consolidation of all the presently available information sources. In recent years, in cooperation with the Department of Special Geodesy of the Faculty of Geodesy of the Czech Technical University, a number of point clouds have been collected with varying levels of accuracy and point densities using static laser scanners. The gallery had previously been described via 2D situational drawings, which did not provide either the information necessary on the spatial arrangement or comprehensive information on the mine complex.

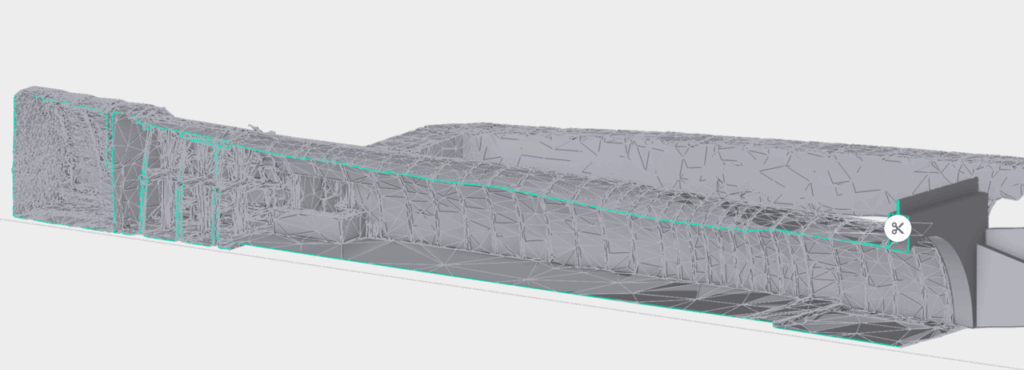

The digitalisation process involves the re-measurement of certain areas of the underground complex applying a higher point cloud density, e.g. the former compressor room, control room and the connecting corridor between the main access corridor and the compressor room. In addition, previously unmeasured areas have been scanned, e.g. the machine room, the mine excavations in the Čelina section at a height of +40m, the former explosives storeroom, etc. In addition to static scanners, an Emesent handheld scanner was used for measurement purposes. A drone was used to measure the entrance portals and the adjacent areas.

All the clouds were subsequently transformed into S-JTSK coordinates and uploaded to a common data environment.

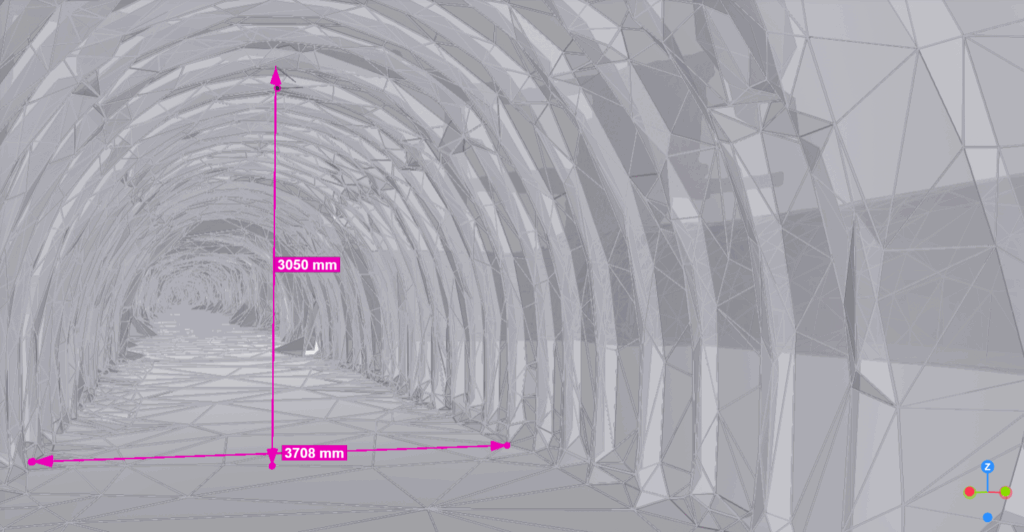

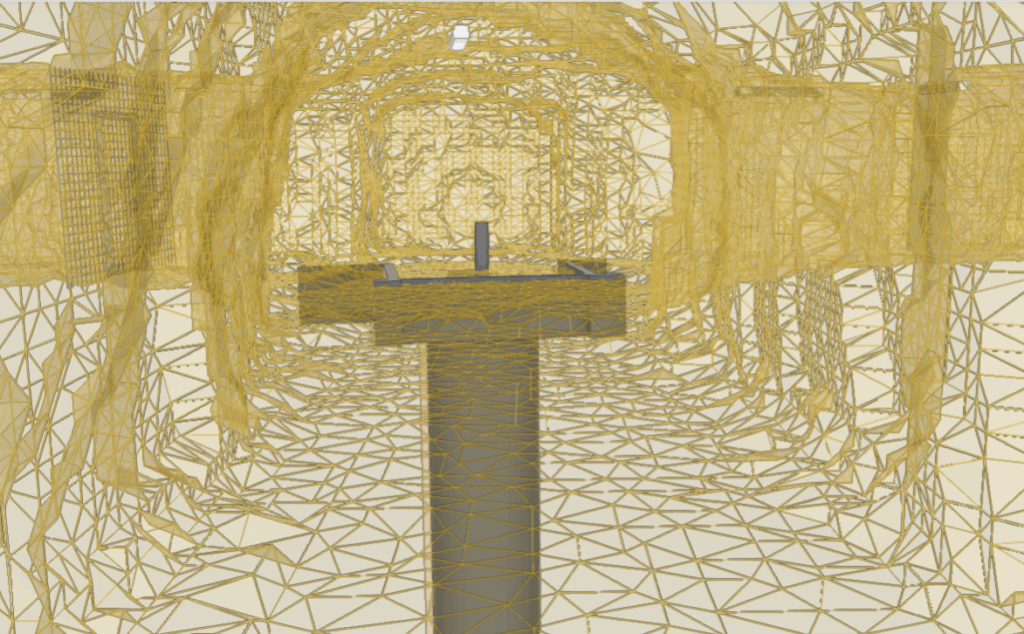

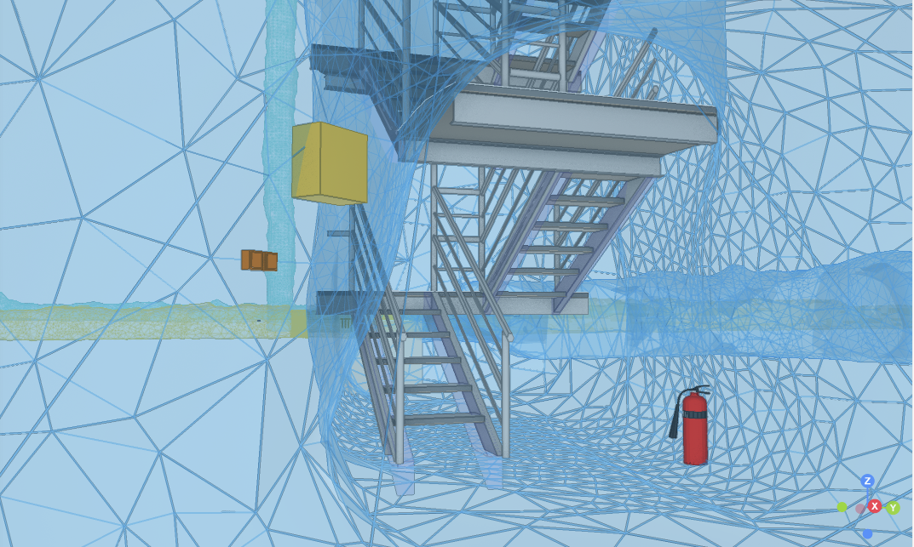

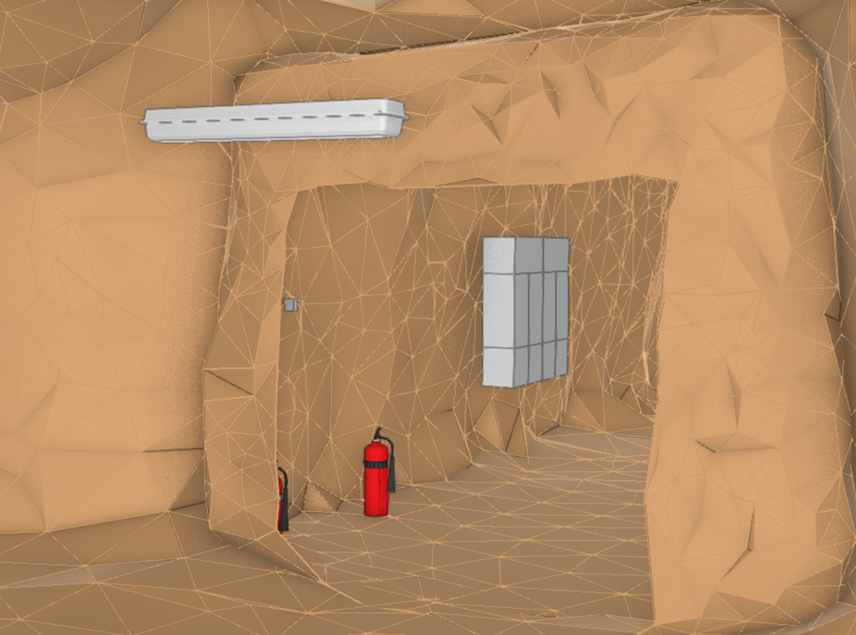

The clouds were then segmented into envelope clouds of the gallery and infrastructure element clouds. A triangular model of the corridors was created from the envelope clouds and the element clouds were employed for the identification of the individual elements and their modelling in CAD software. The triangular models were created at 3 different levels of detail so as to ensure their effective use in different situations.

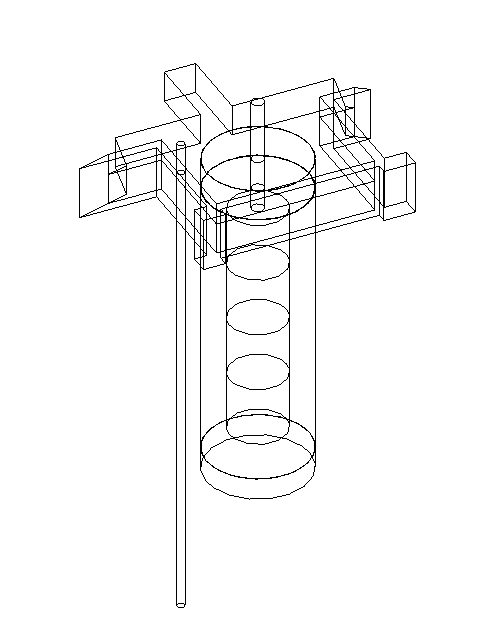

The digitalisation of the stairs in the underground section of the Čelina area was the subject of a separate section of the project. The stairs consist of an iron structure with a total height of 40 m with several landings, steps and railings. Due to the irregularity of the vertical space that contains the stairs, its various components are also irregular. The distances and shapes of the landings, the lengths and types of the railings and the spacing of the steps all differ considerably. In order to construct an accurate 3D model, it was, therefore, necessary to model each individual element of the stairs separately according to the point cloud base.

Phase 1.b

– BIM profession models

The model is being created applying the federative approach, i.e. it has been split into components both spatially and in terms of the professional requirements. This ensures the potential for the further expansion of the model according to the systems installed.

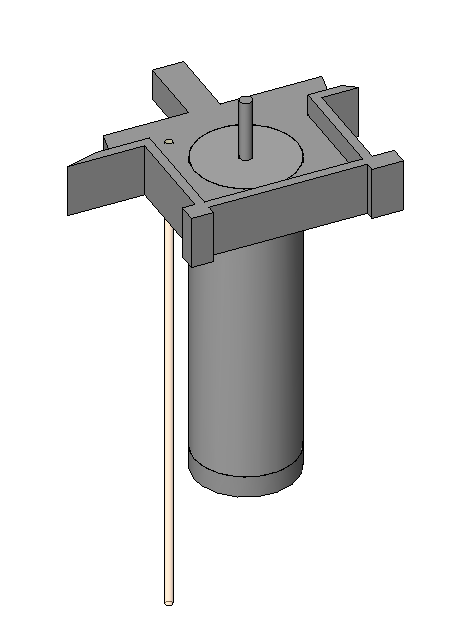

A custom-built BIM model is being created via the addition of non-graphic information (the manufacturer, revisions, installation, etc.) to the individual element models (sensors, electrical distribution boxes, switches, sockets, telephones, cameras, fire extinguishers, electrical and water distribution systems, etc.).

Due to the extensive dimensions of the gallery and the wide variety of the installed elements, the implementation of the model commenced in the Mokrsko – west gallery face (in the immediate vicinity of the ongoing MATEO project – Optimisation of materials and technologies for radioactive waste disposal in deep geological repositories).

This will serve to verify both the support provided by the model for the overall project and the potential for integrating research information into the model.

Phase 2

creation of a digital shadow

The next step will comprise the importing of the completed model into the digital twin platform of the Czech Technical University in Prague. This will be accompanied by the commencement of the connection of the various elements installed in the gallery – sensors, gauges and other elements that enable digital communication. Those systems that do not allow for such communication will be equipped with control elements with the potential for digital communication. This will ensure the comprehensive monitoring of the various gallery systems.

Phase 3

transition to the digital twin platform

The gradual evolution of the digital twin platform, including the anticipated use of AI technology, will involve the integration of model → reality management functionalities. This will enable the comprehensive management of the various technologies within the gallery without the need for the physical presence of humans. This principle is in complete synergy with newly-implemented autonomous robotisation projects.

Obecná teze

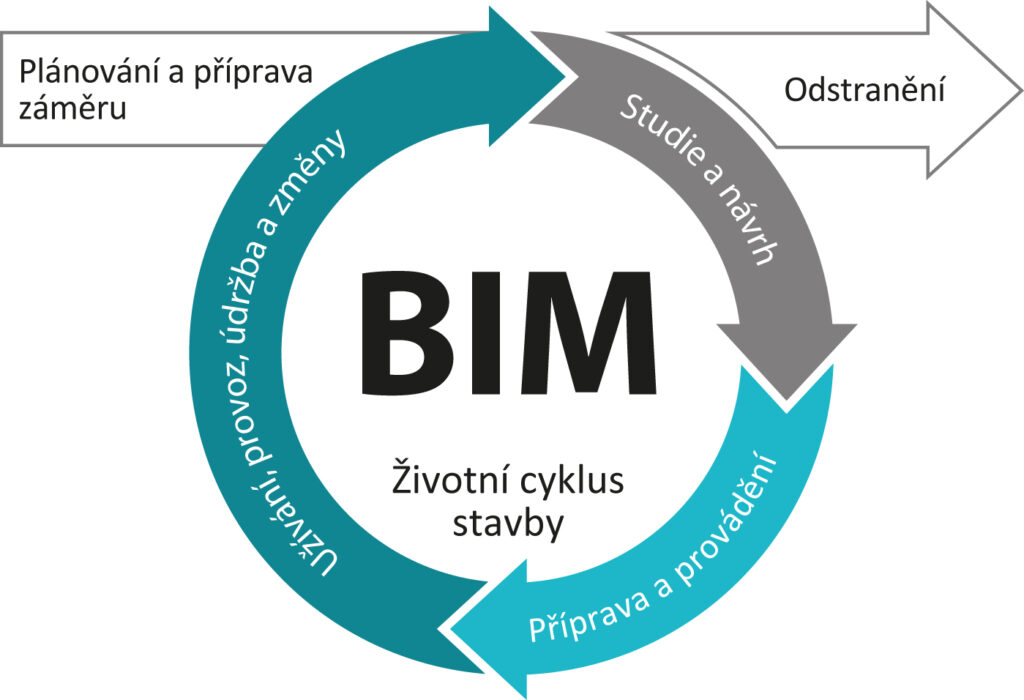

BIM (Building Information Modelling) refers to the process of creating and managing data on structures throughout their life cycle. Building information models essentially comprise digital models (digital twins) that represent physical and functional structures, including their various characteristics.

The exchange and sharing of data and information on structures is conducted via the use of the open file format IFC (The Industry Foundation Classes), which was developed by the buildingSMART international association. Digital models serve as open databases of information on structures with concern to their design, construction and operation.